Want Wichita Falls stone paving experts? You'll get long-lasting granite, limestone, travertine, and flagstone engineered for UV stability, weather resistance, and slip resistance. Our team will configure grades, drainage, and load classes; build compressed layered bases; set tight joints with polymeric sand; and seal with professional surface treatments. Count on laser-leveled bedding, sturdy perimeter restraints, 1-2% slopes, and permeable coating. Suitable for patios, pool decks, and driveways with vehicle traffic. Keep going to discover options, specifications, maintenance, pricing, and warranty.

Main Highlights

- Wichita Falls specialists in landscaping pavers engineered for freeze-thaw durability, high load resistance, and UV-fast, anti-slip finishes.

- Coordinated site development: drainage systems, grade levels, utility locations, traffic patterns, and project phases organized for smooth, problem-free implementation.

- Professional base building: establish proper frost depth, install compressed aggregate lifts to 95% compression, create proper 1-2% drainage grade, and set perimeter restraints.

- Validated stone parameters encompass dense limestone, granite, sandstone, and travertine with slip-resistant surface treatments and dimensional measurements tailored to foot traffic and vehicle applications.

- We install expertly designed exterior living spaces using precision-laid patterns combined with professional joint systems, quality sealers, plus easy-care features.

What Makes Natural Stone Pavers Exceptional in North Texas

Given that North Texas sees dramatic changes from hot summers and freezing winters, natural stone pavers are an excellent choice by providing outstanding thermal durability, compressive strength, and durability. You require materials that will not fail under the region's extreme weather. Premium quarried stone materials sourced locally provide reduced water absorption, minimizing freeze-induced microcracking. Their interconnected installation accommodates natural expansion without structural issues, while high PSI ratings provide strong vehicular support.

You'll also benefit from UV-fast color stability and superior slip resistance with textured and thermal finishes. Dimensional accuracy ensures tight joints, significantly reducing deterioration of bedding sand. With proper base depth and graded aggregates, these materials effectively handle stormwater, reducing subgrade pumping. Using local stone suppliers shortens lead times, maintains costs, and provides traceable specifications, enabling you to accurately align performance, appearance, and lifecycle value.

Our Design-to-Installation Process

We start by conducting collaborative site planning that analyzes terrain slopes, water management, structural requirements, and circulation routes to determine precise heights and boundary limitations. Our team will select materials, foundation thickness, fabric underlayment, and joint filling to suit soil conditions and performance targets. Our crew then executes a flawless professional installation with precise excavation, compacted aggregate layers, laser-leveled bedding, tight joint alignment, and clean finishing.

Collaborative Site Planning

Before construction begins, thorough site planning harmonizes your vision with property specifications through a systematic, data-driven process. We initiate with a comprehensive site analysis: laser levels, soil probing, drainage tracing, and utility locates determine terrain levels, ground stability, and potential hazards. You'll review comprehensive plans highlighting drainage routes, sun exposure, and usage patterns. Through stakeholder coordination, we coordinate requirements from property owners, designers, and regulatory bodies to avoid issues and streamline permissions.

We transform limitations into practical design parameters-perimeter constraints, foundation depth, and jointing details connected with load category and freeze-thaw exposure. Implementation strategies coordinate accessibility, supply placement, and equipment paths to preserve existing infrastructure. You get a precise scope, measured materials, parameters, and a schedule coordinated with seasonal timing and verification checkpoints.

Seamless Professional Installation

Once approvals, specs, and phasing are set, our team carries out a systematic construction sequence that matches the design package. You'll observe benchmarks being validated, utilities properly marked, and access routes secured to protect neighboring surfaces. We position materials for efficient operations, then proceed with subgrade testing, excavation to specification, and geotextile installation.

The base installation begins with measured lift heights, compression testing, and slope analysis. Using precision instruments, we set up stringlines and laser levels to control grade and slope. Perimeter barriers are anchored, base course is screeded, and blocks are placed following the layout, with exact gap management. Field supervision guarantees organized workflow, coordinated supply drops, and environmental impact mitigation. We complete the project with machine-driven compression, sand-lock installation, surface cleaning, and punch-list verification, producing a durable, precisely executed installation.

Natural Stone Options: From Flagstone to Travertine and Limestone

You'll analyze and compare flagstone designs and dimensions to accommodate traffic loads, drainage requirements and the required traction levels. We'll explain travertine's advantages - cool-to-the-touch surface, superior durability, and color stability - to assist in designing outdoor living spaces that withstand high temperatures. You'll also evaluate limestone's resilience characteristics, including hardness, absorption, surface treatment, and sealing requirements, to ensure enduring quality in Wichita Falls' freeze-thaw and UV conditions.

Different Flagstone Types and Applications

While every location has specific needs, flagstone, travertine, and limestone offer shared core benefits for durable, high-traction paving. For flagstone applications, opt for quartzite, slate, or sandstone in natural cleft or calibrated dimensions to achieve ideal grip, strength, and installation time. Choose irregular pieces for natural designs, or choose rectangular cuts for tighter joints and faster compaction. Specify 1.5-2-inch thickness for driving surfaces, 1-1.25 inches for pedestrian zones. Place on compacted foundation with joint sand to ensure proper drainage and joint integrity. Include micro-slope (1.5-2%) directing water from buildings, with edge drainage where grade is limited. Add penetrating stone treatment to prevent damage and staining. Detail expansion at hardscapes, and service joint sand annually to maintain stability and grip.

Benefits of Travertine: A Complete Guide

Because Wichita Falls sees extreme temperature swings, travertine proves ideal for climate comfort, traction, and durability. You'll immediately notice its exceptional thermal properties: the light-colored, porous stone helps deflect solar gain and distributes heat, maintaining pool decks and patios cooler to walk on. The built-in tumbled finish delivers excellent wet and dry grip, reducing slip hazards without rough surface patterns.

You also achieve modular uniformity. Dimensional cuts install tightly, reducing gap movement and making drainage angles easier to 1-2%. After appropriate sealing, travertine withstands de-icing salts more effectively than many composites and tolerates freeze-thaw cycling with minimal deterioration due to its natural porosity and capillary behavior. With sustainable procurement alternatives, you can choose quarries with sustainable water management, low-embodied-energy processing, and certified supply chain records.

Limestone Durability Factors

Though limestone offers a classic, uniform appearance for Wichita Falls hardscapes, its durability depends on density class, pore structure, finish, and maintenance. You'll get improved weather durability from compact, minimally porous limestones (Class II-III) that restrict water absorption and freeze-thaw cycling. Examine pore size distribution; smaller micro-pores minimize capillary uptake and salt website crystallization. Fossil presence is important: compact micritic structures outperform shelly beds with voids that can deteriorate under traffic.

Specify a heat-treated or bush-hammered finish to provide grip while maintaining pore integrity; refrain from aggressive acid washing that weakens calcite bonds. Protect with a breathable, penetrating silane/siloxane; renew every 18-24 months following absorption analysis. Install polymeric sand and positive drainage (1-2% slope) to reduce ponding. For driveways, select minimum 8,000 psi compression strength and 1.5 to 2 inch thickness.

Patios, Walkways, and Outdoor Living Spaces

Enhance the appearance and durability of your property with premium stone patios and outdoor features crafted for endurance. We provide expertly graded foundations, compressed to optimal 95% density, and edge restraints that lock courses against migration. We select stone thickness to meet structural needs-1.5-2.25 inches for patios and walkways-placed on engineered sand or graded aggregate for water management.

Engineered for practicality: create outdoor dining areas with precise jointing for stable seating, and include fire features with heat-rated stone, noncombustible clearances, and concealed gas lines. We design circulation using ample walkway widths (minimum 42 inches), even rise/run on steps, and textured finishes for secure footing. Drain water away from structures with 1-2% fall and subsurface routing to discharge points or French drains.

Pool Decks and Slip-Resistant Finishes

Get exceptional pool deck performance despite continuous water exposure and sunlight when you pair the right stone with proper construction. Improve slip resistance by choosing textured finishes-flamed granite, sandblasted limestone, or shot-blown sandstone-tuned to a measured coefficient of friction. Opt for pale shades to reduce surface temperature; check density and porosity to optimize water permeability with freeze-thaw durability. We install pavers on a stabilized, well-drained base with perimeter restraint, then apply polymeric joint sand to stabilize edges and repel waste. Include expansion joints at prescribed intervals and create a 1-2% gradient from the pool for positive drainage. Choose specific sealing: breathable, penetrating sealers preserve traction without surface buildup. You'll simplify upkeep with routine rinsing and proper pH cleaning.

Custom Driveways That Combine Strength and Beauty

After carefully examining pool decks for grip and drainage specifications, use the same careful approach to driveway installations where traffic, stress, and environmental factors impact every square foot. Choose premium natural stone materials certified for vehicular loads; validate compressive strength ratings, abrasion resistance levels, and winter condition resistance. Utilize integrated dimensional designs to distribute wheel pressure and minimize movement. Select sustainable paving options manufactured with reduced energy impact, and verify pigment durability when exposed to sunlight and de-icing agents.

Engineer water-permeable installations to lower surface water and reduce heave. Implement open-joint layouts matched to high-strength, engineered joint compound that prevents washout and discourages weeds. Adjust patterns-classic layouts-to accommodate traffic vectors and minimize shear at turning zones. Account for winter maintenance, stain protection, and thermal performance. Finish with exact tolerances, clean lines, and complementary borders that boost curb appeal.

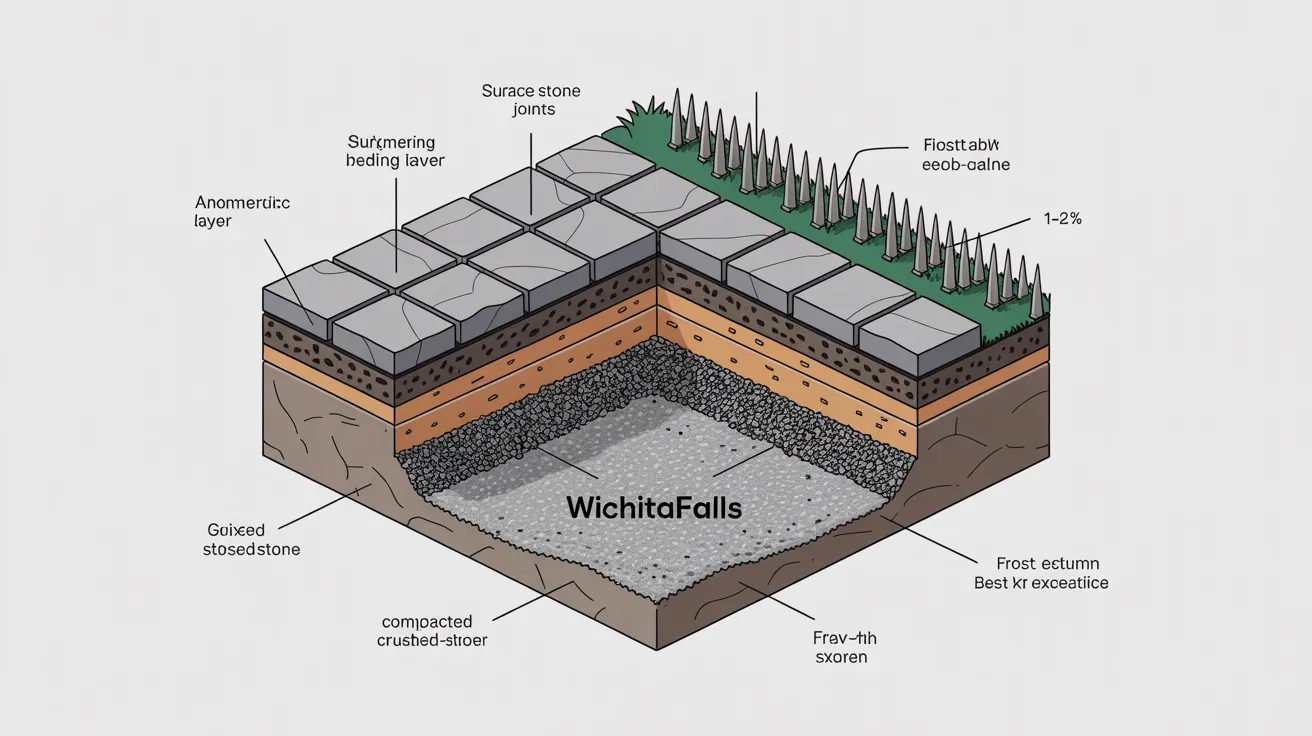

Craftsmanship Details: Base Preparation, Drainage, and Edging

Since performance begins under the surface, treat craftsmanship as a methodical approach: remove soil to frost depth and eliminate organics; test-roll to detect soft spots; then construct a strong foundation. Choose a quality-graded crushed stone for subbase preparation, focusing on angular aggregates for stability. Apply moisture-conditioned lifts (3-4 inches) and check density with compaction testing and pass counts. Set up precise grading methods: create a 1-2% slope away from structures, incorporate trench drains or weep paths where required, and protect edges from displacement.

Lay down a screeded bedding layer (usually 1 inch of concrete bedding sand), maintaining it uncompressed before placing pavers. Secure the area with perimeter restraints-metal or concrete border supports-set on compressed substrate, not soil. Compact and fill against borders, then mechanically set pavers with swept-in sand for structural bonding.

Long-Term Care, Maintenance, and Sealing

Prioritizing preventive maintenance keeps your natural stone pavers looking beautiful for many years to come. Set up a regular cleaning routine: use a low-pressure rinse, gentle stone cleaner, and targeted stain elimination using specially formulated poultices for difficult oil, rust, or organic stains. Examine joints every three months; conduct joint upkeep by re-applying polymeric sand, thoroughly compacting, and lightly misting to stabilize perimeters and prevent weed intrusion. Monitor height differences, fissures, and rocking units; re-level and adjust as necessary to maintain load bearing.

Seal once every two to three years based on porosity and traffic. Select permeable sealants that penetrate that provide UV protection without changing vapor transmission or sheen, and check slip coefficients for wet areas. Preserve edge barriers, clean drainage channels, and use de-icers chloride-free. Record product details, application periods, and coverage to schedule timely renewals.

Transparent Pricing Information, Scheduling, and Warranty Coverage

Even before the design is finalized, we create a detailed estimate showing individual prices for key elements like excavation, base, bedding, stone selection, cutting, edge restraints, drainage elements, jointing sand, sealers, and mobilization. We provide detailed estimates featuring quantities, production rates, labor hours, and disposal fees, preventing surprise overruns. Our team locks in pricing within defined tolerances and explicitly outline allowances for infrastructure challenges or subgrade remediation.

We maintain precise scheduling control: we validate stone delivery times, organize crew schedules, and methodically coordinate excavation, base compaction, stone setting, and joint stabilization. Offering scheduling flexibility, you have the freedom to choose on-site consultations, evening installations, or sequential work to reduce interference with your routine.

Our warranty agreement protects against heave, settlement, joint failure, and edge restraint movement, featuring detailed maintenance guidelines and a simplified claim procedure.

Popular Questions

Are 3D Renderings and Augmented Reality Design Previews Available?

Indeed. We provide 3D visualization and augmented reality views for planned layouts. We capture site measurements, create a accurate digital model, and utilize material libraries corresponding to your selections. We'll show you camera paths, lighting conditions, and drainage slopes. On mobile, AR places the design at true scale, allowing you to move through the design, toggle finishes, and contrast design patterns. We implement changes rapidly, produce dimensional plans, and deliver material specifications matching your approved render.

Can You Match Existing Stone for Partial Renovation Projects?

Absolutely, we provide accurate stone matching for partial updates. Leading with savvy, integrated approaches, we ensure perfect color matching through digital color measurement, batch verification, and finish profiling. We map material characteristics, porosity, and finish to ensure consistency. For seamless transitions, we micro-bevel and tune seam spacing, mortar tint, and surface texture to create seamless joins. When original materials are unavailable, we identify matching alternatives and carefully weather materials for seamless integration.

What Lead Times Should I Expect During Peak Seasons and Holidays?

Processing times during busy seasons and holidays generally span from 3-6 weeks, depending on project scope, material availability, and permitting requirements. Extended durations are common for custom cuts, specialty finishes, and complex drainage or base preparation. We finalize schedules following site verification and final drawings. Anticipate reduced rush availability and potential holiday surcharges from vendors and freight carriers. To minimize delays, approve material selections early, arrange for key materials in advance, and allow flexibility for weather conditions and inspection scheduling.

Can You Assist With HOA and City Permit Requirements?

We provide full HOA coordination and permit facilitation support, so you won't face bureaucratic delays. You'll get a dedicated checklist, certified site plan, material specs, and drainage/runoff documentation customized for HOA requirements. We manage building plans, utility location, boundary confirmation, and permit applications via the municipal system. If revisions are needed, we make quick adjustments and handle updates efficiently. Furthermore, you'll get project scheduling, inspection scheduling, and completion documents to maintain requirements and ensure timely completion.

Do Eco-Friendly and Permeable Pavers Qualify for Stormwater Credits?

Absolutely. You can install sustainable permeable pavers expressly developed to qualify for stormwater credits. These systems use specially graded aggregate beds, large-void joints, and geotextiles to promote infiltration, minimize runoff, and satisfy BMP criteria. You'll pick porous concrete pavers, permeable asphalt, or interlocking permeable pavers based on soil permeability, subgrade CBR, and water management objectives. Include maintenance plans (vacuum sweeping), hydrologic calculations, and manufacturer specs to demonstrate adherence for credit approval.

Wrapping Up

You're not just selecting pavers-you're creating a hardscape built to last. From proper base preparation to joint securing and drainage slopes, every detail works together seamlessly. You'll get non-slip textures around pools, weight-tested driveways, and water-resistant patio surfaces. We'll specify the ideal materials, sealants, and upkeep strategy, then lock in clear costs and scheduling. Want to change ground into foundation? Let's design your vision and construct it to endure North Texas conditions.